GREENMECH

GreenMech EVO 205D SURE-Trak

GreenMech EVO 205D SURE-Trak

SKU:EVO205D_SURE

Available to Order (Subject to Manufacturer Availability)

Oversized Shipping Rates Apply

View our shipping policy here

Couldn't load pickup availability

The EVO 205D represents everything that’s evolutionary in an 8 inch chipper. We’ve listened to the industry and used all our design and manufacturing experience to develop the machine that will deliver exactly what you’ve been looking for.

The backbone of the EVO 205D’s design is based on a deep beam, high tensile steel chassis which creates tremendous strength and ensures a robust performance. A new, generous in-feed hopper measuring 1250mm x 700mm, means that free-flow of bulky material can be handled without having to trim to a more manageable size. As the material passes through twin, horizontal feed rollers, GreenMech’s Smart Sense No-Stress system automatically manages the throughput of material to maximise chipping efficiency.

The Kubota Stage V–compliant 50hp diesel engine powers the chipping system, the heavy duty flywheel featuring 2 banks of 3 discs. GreenMech’s renowned Disc Blade System allows rotation of each disc’s cutting edge and extends the sharpening period to only once in approximately 150 hours. This is a feature that reduces downtime, cuts maintenance and maximises working performance.

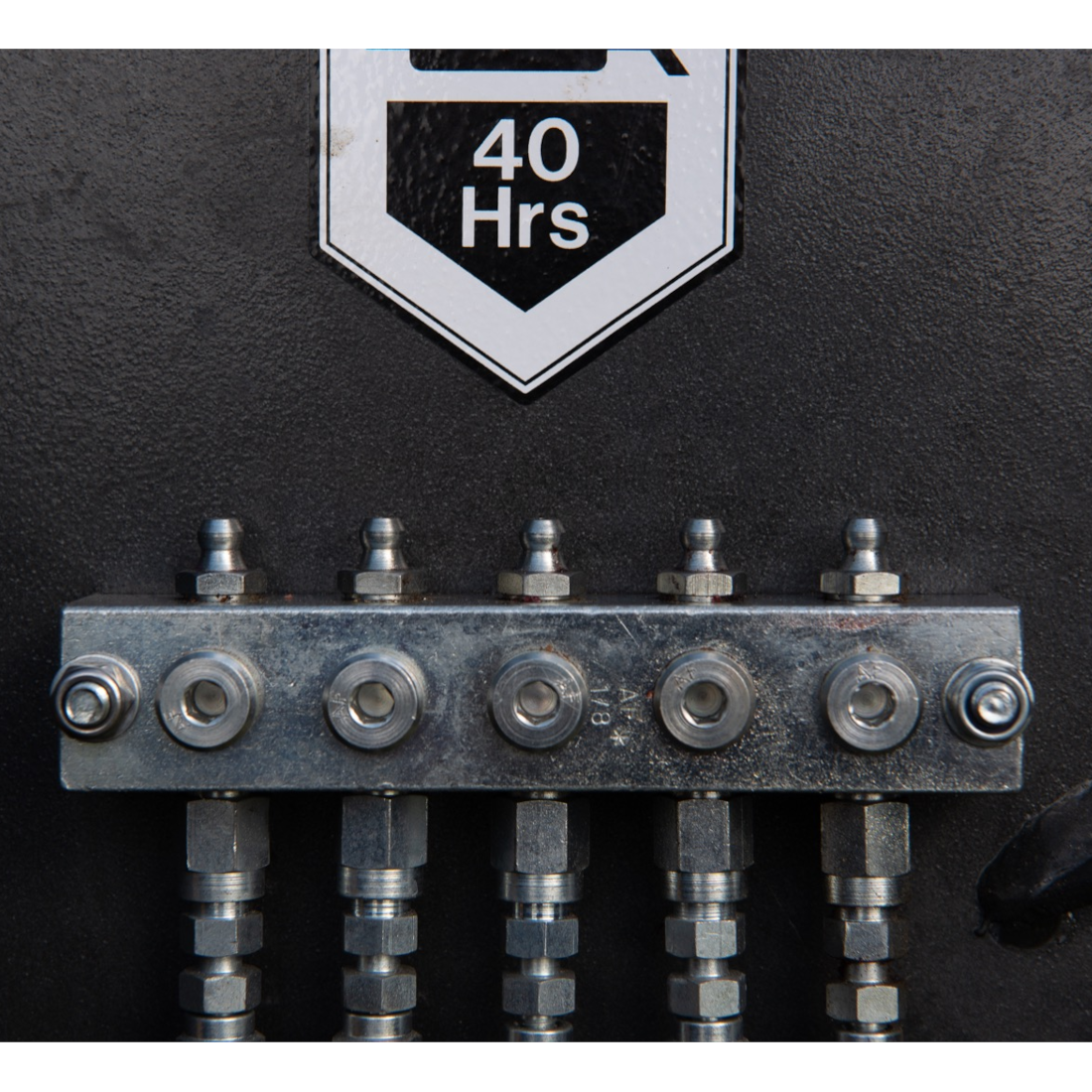

Maintenance is simple via the hinged steel bonnet, along with a centralised grease point and easy -to -remove shear bars.

Features

Features

NEW "SMART SENSE" CONTROLLER

- Provides “no-stress” overload protection, automatic load detection and a range of engine and chipper data to ensure optimum performance.

SURE-TRACK SYSTEM

- The independently pivoting track assemblies allow each track to maintain contact with the ground while following the differing contours and so provide a surer footprint and improved stability.

GROUND CLEARANCE

- Clearance of 250mm with the tracks in and 540mm with the tracks out helps access to sites over demanding terrain.

TRACK OR CHIP

- Console switch ensures machine is either tracking or chipping, so minimising the risk of any accidental operation.

HORIZONTAL ROLLERS

- Gather and grip the material while offering a smooth flow into the processor with reduced lateral movement.

TWIN TRACK DRIVE

- Each track has its own drive motor for improved security and reliability and together provide a tracking speed of 4kph.

Specifications

Specifications

- CAPACITY: 205mm

- ENGINE MAKE: Kubota D 1803-CR-TE4B

- ENGINE OUTPUT: 50hp

- FUEL: Diesel

- CHIPPING FLYWHEEL: Disc Type

- BLADES: 6

- GROUND CLEARANCE: 540mm Max / 250mm Min

- TRACK SPEED: 4kph

- HYDRAULIC FEED ROLLERS: Twin Horizontal

- POWER CONTROL: No Stress

- FUEL CAPACITY (ENGINE): 50 Litres

- HYDRAULIC OIL CAPACITY: 50 Litres

- SPARE WHEEL: N/A

- TONNES PER HOUR: 7

- INFEED CHUTE APERTURE: 1250mm x 700mm

- INFEED THROAT SIZE: 205mm x 270mm

- DISCHARGE CHUTE: 280 Degrees Rotation

- HOUR METRE: Standard

- LENGTH (TRANSPORT): 3860mm Max / 3020mm Min

- WIDTH (TRANSPORT): 2356mm Max / 1550mm Min

- HEIGHT (DISCHARGE CHUTE UP): 2760mm Max

- WEIGHT: 2150 kg

- SOUND POWER LWA: 118 dB(A)

- SOUND PRESSURE LPA: 91 dB(A)

Share